Introduction

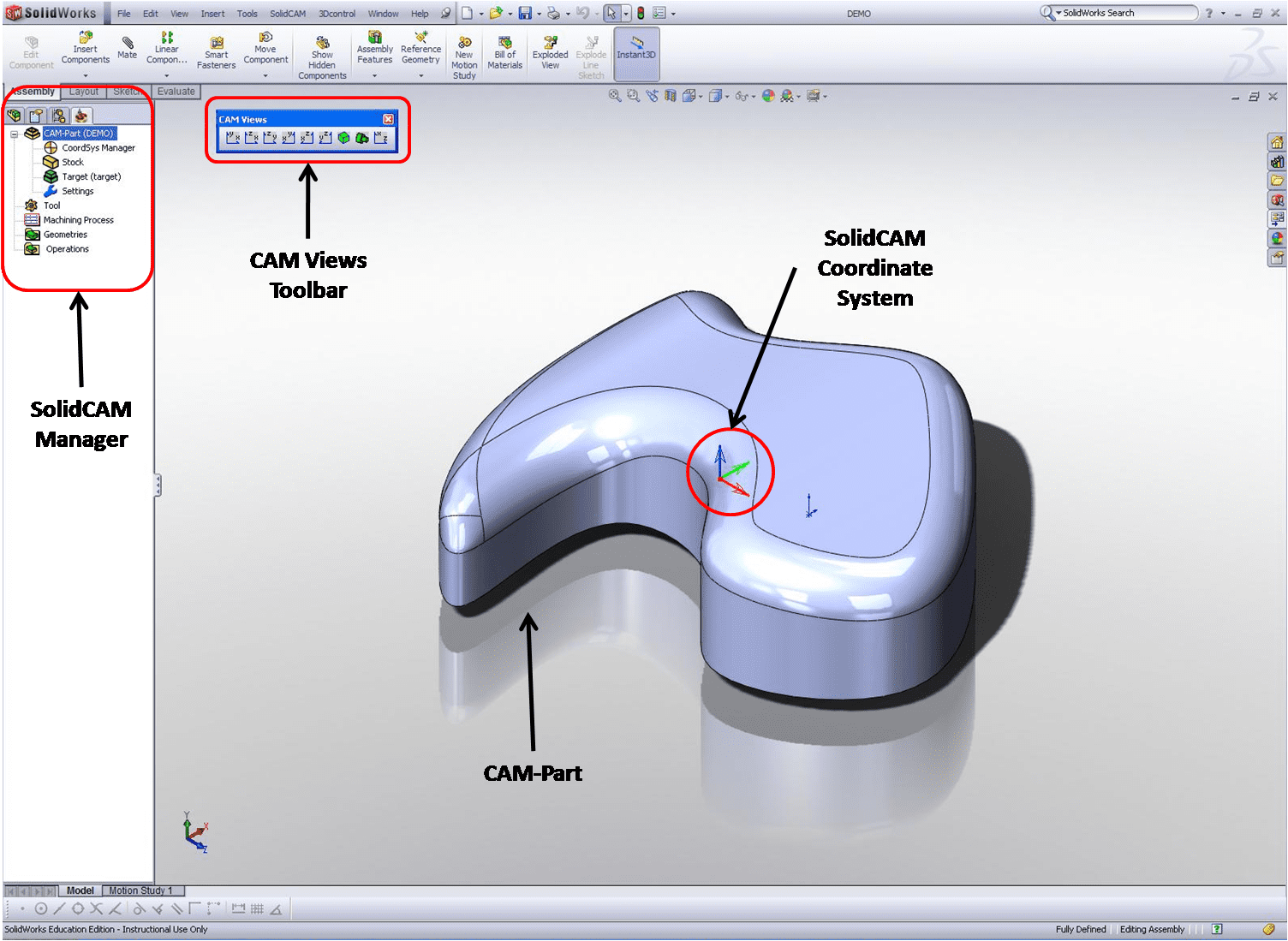

SolidCAM is a powerful CAM (Computer-Aided Manufacturing) software designed to integrate seamlessly with SolidWorks, providing a comprehensive solution for CNC machining operations. Here’s a detailed introduction to SolidCAM for Windows:

Overview:

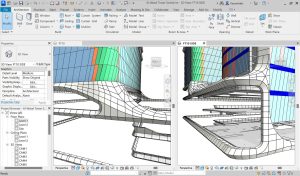

SolidCAM offers a range of tools and features aimed at optimizing the machining process, from 2.5D milling to complex 5-axis simultaneous machining. It operates as an integrated CAM solution within SolidWorks, leveraging its CAD capabilities for seamless transition from design to manufacturing.

Key Features:

- Integration with SolidWorks:

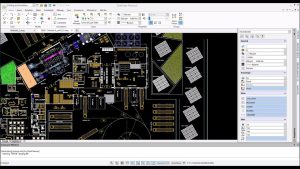

- SolidCAM is fully integrated with SolidWorks, allowing users to work within a familiar CAD environment and eliminating the need for data translations or file conversions.

- CAM Modules:

- Milling: Supports 2.5D milling, 3D milling, high-speed surface milling, and 5-axis machining. It includes features like toolpath optimization, collision detection, and efficient roughing and finishing strategies.

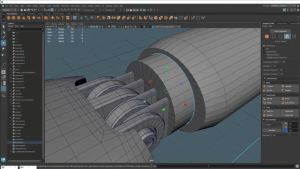

- Turning: Offers comprehensive turning solutions, including automatic roughing, finishing, grooving, threading, and more.

- Mill-Turn: Handles complex multitasking operations, integrating milling and turning processes in a single setup.

- Simulation and Verification:

- Provides simulation tools to verify toolpaths, detect collisions, and ensure machining accuracy before actual production. This helps in reducing errors and optimizing machining processes.

- Toolpath Optimization:

- Uses advanced algorithms for efficient toolpath generation, optimizing cutting strategies based on material, tooling, and machine capabilities.

- Post-Processing:

- Generates CNC machine-specific G-code using customizable post-processors, ensuring compatibility with a wide range of CNC machines and controllers.

- Automation and Customization:

- Supports automation through feature-based machining and macros, allowing users to automate repetitive tasks and customize workflows according to specific manufacturing requirements.

- Support for Various Machining Operations:

- Includes support for drilling, contouring, pocketing, and other essential machining operations, catering to a diverse range of manufacturing needs.

- CAM-Partnership:

- SolidCAM partners with various machine tool manufacturers to provide optimized CAM solutions tailored to specific machine capabilities and industry standards.

Benefits:

- Seamless Integration: Integrates directly with SolidWorks, enabling a streamlined workflow from design to machining.

- Efficiency: Optimizes machining processes, reduces cycle times, and minimizes scrap through advanced toolpath strategies.

- Accuracy: Ensures machining accuracy and surface finish quality through simulation and verification tools.

- Versatility: Supports a wide range of machining operations and CNC machine types, accommodating different manufacturing requirements.

Conclusion:

SolidCAM for Windows is an advanced CAM software solution that enhances productivity and efficiency in manufacturing processes. By leveraging its integration with SolidWorks and powerful machining capabilities, SolidCAM enables engineers and CNC programmers to achieve optimal results in CNC machining operations.

Details

__

__

July 14, 2024

Paid

No ads

Windows

Multilanguage

661

__

__

Download