Introduction

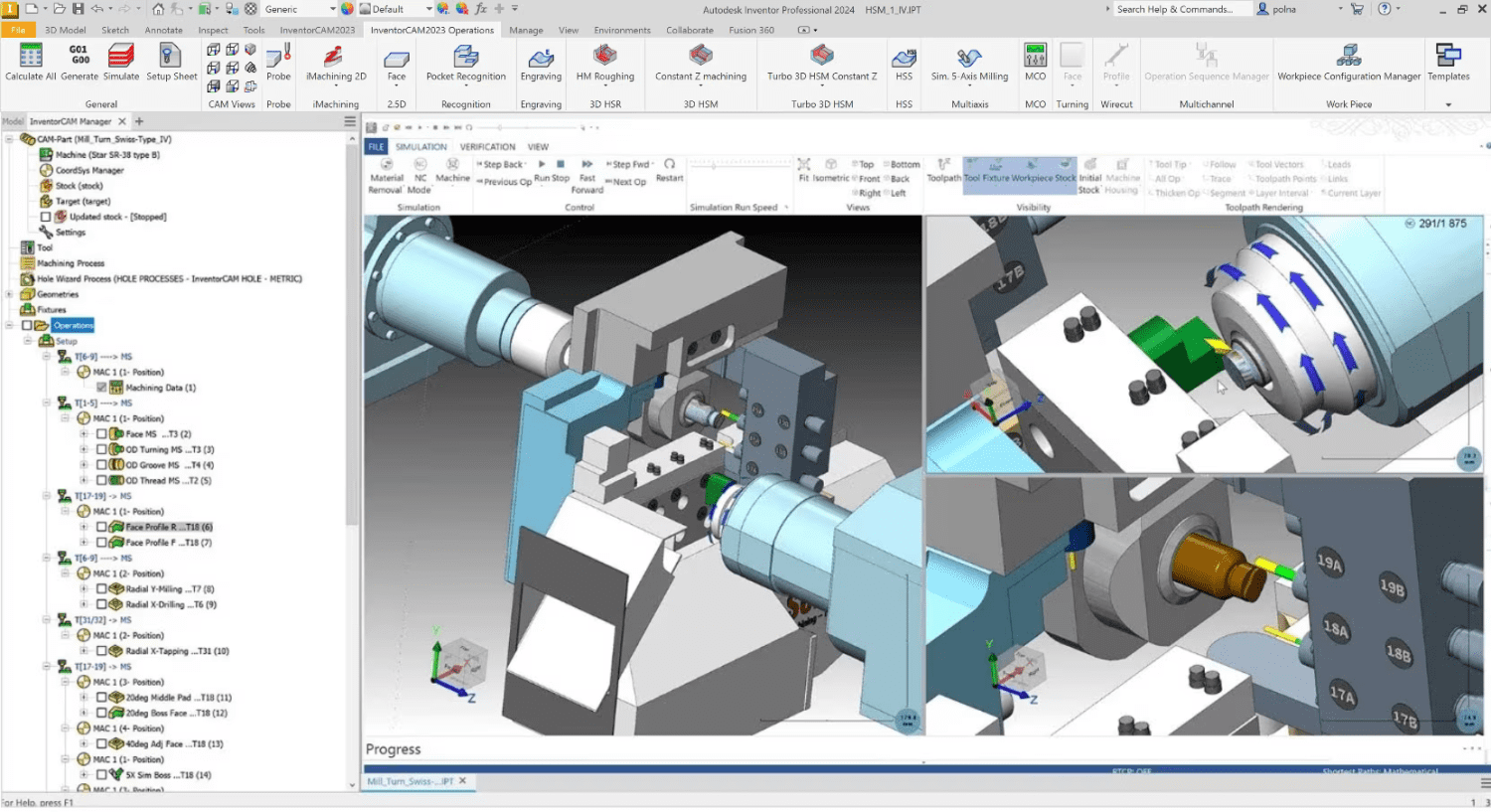

InventorCAM is a powerful integrated CAM (Computer-Aided Manufacturing) solution designed to work within Autodesk Inventor. It provides comprehensive machining capabilities, enabling users to seamlessly transition from design to manufacturing. Here’s an overview of its key features and functionalities:

1. Integration with Autodesk Inventor

InventorCAM is fully integrated with Autodesk Inventor, which means it operates directly within the Inventor environment. This integration ensures a smooth workflow between CAD design and CAM operations, reducing the need for data translation and minimizing errors.

2. Comprehensive Machining Strategies

InventorCAM offers a wide range of machining strategies, including:

- 2.5D Milling: For simple milling tasks, such as drilling and pocketing.

- 3D Milling: For more complex operations, like contouring and surface machining.

- 4/5-Axis Milling: Supports advanced multi-axis machining for intricate parts.

- Turning: For cylindrical parts, including standard and complex turning operations.

- Drilling & Tapping: Comprehensive tools for creating holes and threads.

3. Toolpath Generation

The software provides powerful toolpath generation capabilities, allowing users to create precise machining paths for various operations. This includes roughing and finishing paths, adaptive clearing, and more. The toolpaths are optimized to reduce machining time and enhance part quality.

4. Simulation and Verification

InventorCAM includes simulation tools to visualize and verify toolpaths before actual machining. This feature helps identify potential issues, such as collisions or tool interference, ensuring that the final part will be manufactured as intended.

5. Post-Processing

The software comes with a wide range of post-processors for different CNC machines, ensuring that the generated G-code is compatible with various equipment. Custom post-processors can also be created or modified as needed.

6. Advanced Features

- Feature Recognition: Automatically recognizes and extracts machining features from the CAD model.

- Knowledge Base: Incorporates a library of machining strategies and parameters, which can be customized to suit specific requirements.

- Integration with ERP/MRP Systems: Facilitates the flow of manufacturing data to enterprise resource planning (ERP) or material resource planning (MRP) systems.

7. User-Friendly Interface

InventorCAM’s user interface is designed to be intuitive, with context-sensitive menus and a streamlined workflow that integrates seamlessly with Autodesk Inventor’s design environment.

8. Support and Updates

The software is supported by a range of resources, including documentation, tutorials, and customer support. Regular updates ensure compatibility with the latest versions of Autodesk Inventor and introduce new features and enhancements.

Benefits

- Increased Efficiency: Direct integration with Inventor reduces the time and effort required to prepare designs for manufacturing.

- Improved Accuracy: Precise toolpath generation and simulation help ensure accurate machining and high-quality parts.

- Enhanced Flexibility: Supports a wide range of machining operations and can be tailored to different manufacturing needs.

InventorCAM is a robust solution for users of Autodesk Inventor who need to streamline their manufacturing processes and improve productivity.

Details

2024 SP0

Autodesk

August 10, 2024

Paid

No ads

Windows

Multilanguage

479

__

__

Download