Introduction

CAMWorks is a comprehensive CNC (Computer Numerical Control) machining software designed for SolidWorks, a popular CAD (Computer-Aided Design) application. Here’s a detailed introduction to CAMWorks:

Overview

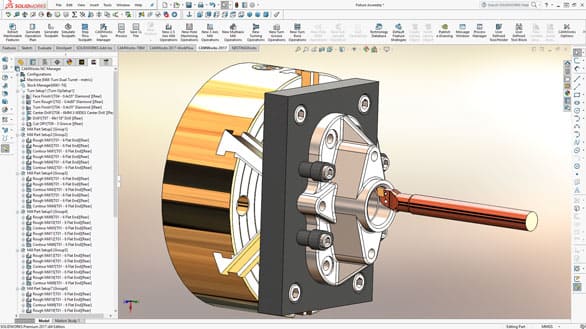

CAMWorks integrates seamlessly with SolidWorks, providing a fully integrated solution for creating and managing CNC machining operations directly within the SolidWorks environment. It enables users to generate toolpaths and G-code for various types of machining processes, including milling, turning, and multi-tasking operations.

Key Features

- SolidWorks Integration:

- Embedded Functionality: CAMWorks operates as an add-in within SolidWorks, which means users can work within the familiar SolidWorks interface without needing to switch to a separate CAM system.

- Feature Recognition: It can automatically recognize and classify features in SolidWorks models, such as holes, pockets, and bosses, simplifying the setup process for machining operations.

- Advanced Machining Capabilities:

- 2.5D and 3D Milling: Supports both 2.5D and full 3D milling operations, allowing for the creation of complex toolpaths for intricate parts.

- Turning and Mill-Turn: Provides extensive support for turning operations as well as combined mill-turn machining, which integrates both milling and turning processes in a single setup.

- Multi-Axis Machining: Includes capabilities for 4-axis and 5-axis machining, which is essential for complex parts requiring multiple angles and orientations.

- Automated Toolpath Generation:

- Feature-Based Toolpath Generation: Automatically generates toolpaths based on recognized features, reducing the need for manual setup and configuration.

- TechDB (Technology Database): Maintains a database of cutting tools and machining parameters, enabling users to apply consistent and optimized settings across different projects.

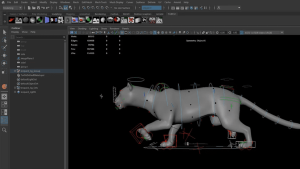

- Simulation and Verification:

- Toolpath Simulation: Provides simulation tools to visualize and verify toolpaths before actual machining, helping to identify and correct potential issues.

- Collision Detection: Includes features for detecting collisions between the tool, workpiece, and machine components to prevent errors and damage.

- Post-Processing:

- Customizable Post-Processors: Supports a wide range of post-processors to generate G-code compatible with various CNC machines. Users can also create or modify post-processors to meet specific machine requirements.

- Ease of Use:

- Intuitive User Interface: The interface is designed to be user-friendly, leveraging the existing SolidWorks environment to minimize the learning curve.

- Integration with SolidWorks Tools: Utilizes SolidWorks’ design and analysis tools, making it easier to manage and modify CAM operations in conjunction with CAD designs.

Benefits

- Increased Efficiency: Streamlines the workflow from design to manufacturing, reducing the time and effort required to set up and execute machining operations.

- Improved Accuracy: By leveraging feature recognition and automated toolpath generation, CAMWorks helps improve the accuracy of machined parts.

- Reduced Errors: Integrated simulation and collision detection help identify potential issues before physical machining begins, reducing the risk of errors and material waste.

- Flexibility and Customization: Offers extensive customization options for toolpaths and post-processing, making it adaptable to a wide range of machining scenarios and machine types.

Use Cases

- Manufacturing: Ideal for manufacturers who need to convert SolidWorks designs into CNC machine instructions for producing parts and assemblies.

- Prototyping: Useful for prototyping and iterative design processes where quick adjustments and modifications are needed.

- Complex Parts: Beneficial for creating complex parts that require multi-axis machining and advanced toolpath strategies.

Overall, CAMWorks provides a powerful and integrated solution for CNC machining within the SolidWorks environment, enhancing productivity and accuracy in the manufacturing process.

Details

2024 SP3

HCL Technologies Limited

August 10, 2024

Paid

No ads

Windows

Multilanguage

428

__

__

Download